PLCs and Industrial Automation: Improving Process Control and Safety

In the world of industrial automation, Programmable Logic Controllers (PLCs) have become a vital component in controlling various processes and machines. PLCs are essentially small, modular, and ruggedized computers that are designed specifically to control industrial processes, making them ideal for use in a wide range of industries, including manufacturing, oil and gas, water treatment, and more.

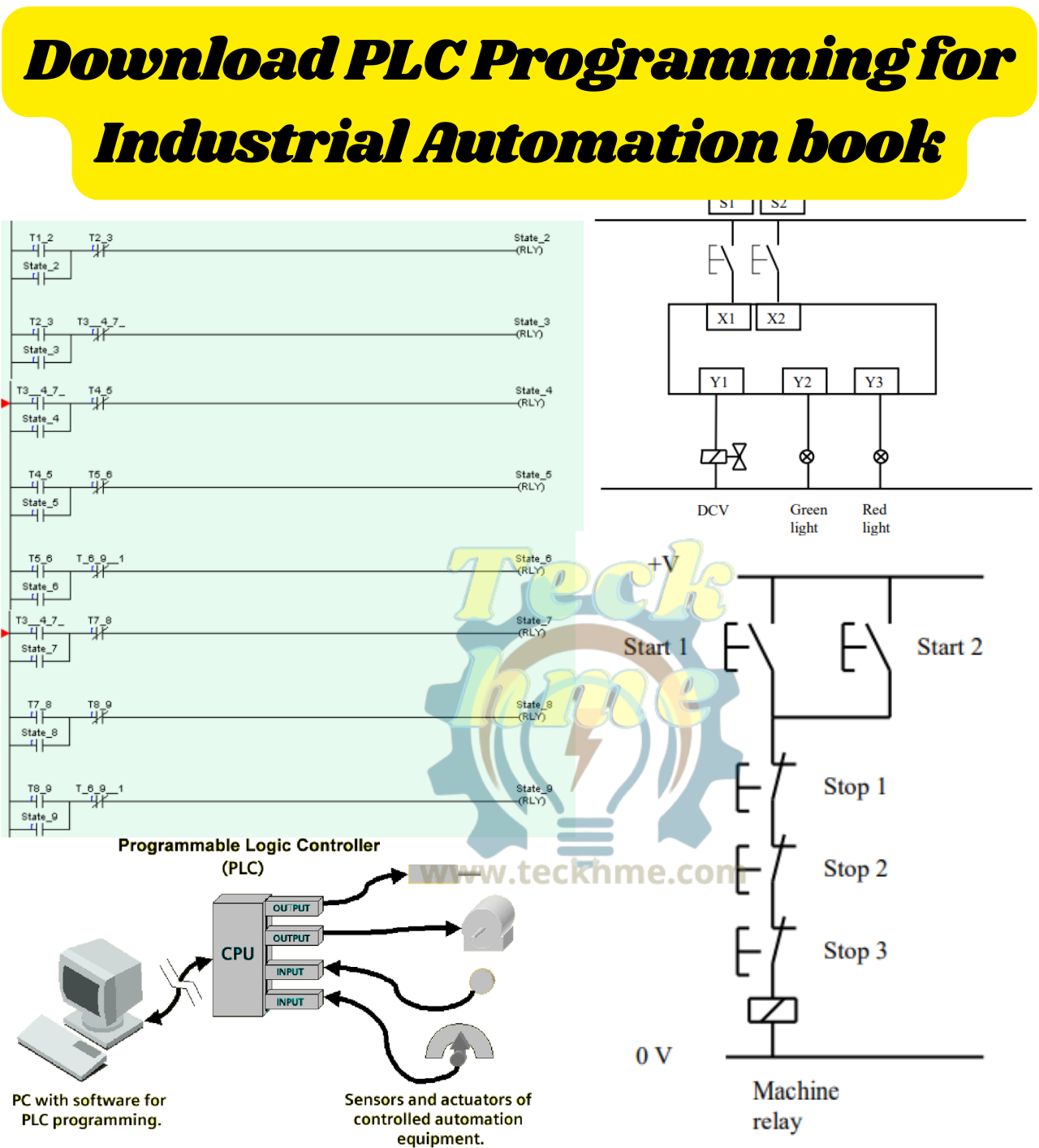

PLC programming is the process of writing code to control the operations of a PLC. This programming can be done using a variety of programming languages, including Ladder Logic, Function Block Diagram (FBD), and Structured Text (ST). Regardless of the programming language used, the goal of PLC programming is to write code that ensures the safety of the equipment and personnel, provides reliable and consistent performance, and controls the operations of a process.

Ladder Logic is a graphical programming language that resembles an electrical ladder diagram and is commonly used to control simple processes. It is easy to understand for those familiar with electrical schematics and is suitable for simple control applications. FBD, on the other hand, is a graphical programming language that uses functional blocks to represent the operations of a process and is often used in process control applications. ST, a text-based programming language, is similar to the programming languages used in traditional computers and is often used for complex calculations and for interfacing with other systems.

The use of PLCs in industrial automation has brought numerous benefits, including increased efficiency, improved process control, and increased safety. With PLCs, industrial processes can be automated and monitored, reducing the need for manual intervention and ensuring that processes run smoothly and consistently. Additionally, PLCs provide a level of safety and protection for both equipment and personnel, reducing the risk of accidents and equipment damage.

here is more information on PLCs and industrial automation:

1. Scalability: PLCs are scalable, which means they can be used in a variety of applications, from small, simple systems to large, complex processes. This makes them a versatile solution for a wide range of industrial automation needs.

2. Flexibility: PLCs are highly flexible, which means they can be easily reconfigured to meet changing process requirements. This makes them an ideal solution for industries that are constantly evolving and changing.

3. Reliability: PLCs are designed to be highly reliable and durable, with features such as redundant power supplies, error detection and correction, and rugged enclosures. This ensures that they can withstand harsh industrial environments and provide consistent performance.

4. Integration: PLCs can be easily integrated with other systems, such as sensors, actuators, and other automation equipment. This allows for seamless communication and control of industrial processes, improving efficiency and reducing the risk of human error.

5. Remote Monitoring and Control: With modern PLCs, it's possible to remotely monitor and control industrial processes, providing real-time data and allowing for fast and effective decision-making. This can improve the efficiency and safety of industrial processes, as well as reducing the need for manual intervention.

6. Cost-effectiveness: PLCs are relatively inexpensive compared to other automation solutions and offer a high return on investment. They are also easy to install and maintain, which further reduces costs.

For more information you can download the book PLC Programming for Industrial Automation in below link:

Download now

In conclusion, PLCs and industrial automation have revolutionized the way in which industrial processes are controlled and monitored. With their ability to automate and control processes, improve efficiency, and increase safety, PLCs are an essential component in the world of industrial automation. Whether you're a seasoned engineer or just starting out in the field, understanding the basics of PLC programming and the use of PLCs in industrial automation is an important step towards success in this exciting and dynamic field.

.png)