Programmable Logic Controllers (PLCs) have revolutionized industrial automation, allowing for efficient and precise control of machinery and processes. One of the most widely used programming languages for PLCs is ladder logic. In this article, we will explore the practical aspects of ladder logic programming using RSLogix 500, a popular software platform for PLC programming.

Understanding Ladder Logic

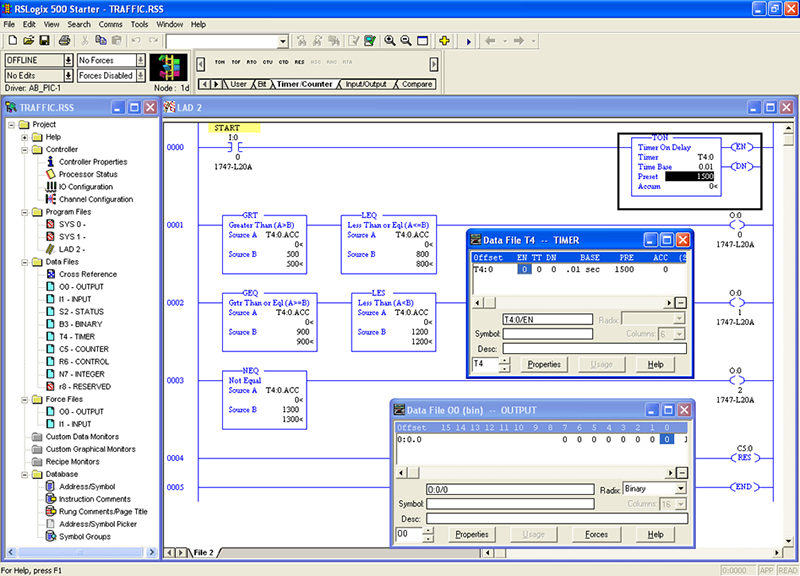

Ladder logic is a graphical programming language that represents control circuits with the use of ladder diagrams. These diagrams resemble electrical schematics, with power rails on the left and right sides and rungs in between. Each rung consists of input contacts, output coils, and various logical functions, such as timers and counters.

RSLogix 500: A Powerful Tool

RSLogix 500 is a software package developed by Rockwell Automation for programming Allen-Bradley PLCs. It provides a user-friendly interface for creating ladder logic programs and offers a comprehensive set of features to facilitate efficient programming and troubleshooting. RSLogix 500 supports various programming languages, but for the purpose of this article, we will focus on ladder logic.

Creating a New Project

To begin programming with RSLogix 500, you first need to create a new project. This involves defining the PLC hardware configuration, such as input/output modules and communication settings. Once the project is set up, you can start developing ladder logic programs.

Designing Ladder Logic Programs

Ladder logic programs are constructed using a combination of input contacts and output coils, interconnected by logical operators. Input contacts represent the conditions that must be met for the rung to become true, while output coils represent the actions to be taken when the rung is true.

RSLogix 500 provides a comprehensive set of instructions and logical operators to build complex control algorithms. You can utilize timers, counters, arithmetic operations, comparisons, and other functions to create sophisticated control strategies tailored to your specific application.

Testing and Debugging

After creating a ladder logic program, it is crucial to thoroughly test and debug it to ensure proper functionality. RSLogix 500 offers several tools for troubleshooting ladder logic, including online monitoring and force commands. Online monitoring allows you to observe the status of input and output signals in real-time, making it easier to identify potential issues. Force commands enable you to manually manipulate the state of inputs and outputs for testing purposes.

Documentation and Maintenance

Maintaining proper documentation of your ladder logic programs is essential for future modifications and troubleshooting. RSLogix 500 provides features for generating reports and documenting program changes. It is good practice to annotate your ladder logic diagrams, providing clear explanations for each rung and its purpose. This documentation will be invaluable to other engineers and technicians working on the system in the future.

Conclusion

PLC programming using ladder logic is a powerful and efficient way to control industrial automation processes. RSLogix 500 provides a practical and user-friendly environment for developing ladder logic programs. By mastering the concepts and tools provided by RSLogix 500, engineers and technicians can create sophisticated control strategies, efficiently troubleshoot issues, and maintain well-documented programs. With the continued advancement of industrial automation, ladder logic programming using tools like RSLogix 500 will remain a crucial skill for professionals in the field.