There is no doubt that electrical maintenance can prevent complex and costly failures. However, most industrial maintenance programs emphasize preventive maintenance for mechanical failures and electrical failures for reactive maintenance. The touchstone is the lack of inventory to fix electrical faults.

Another common symptom of poor electrical maintenance is a lack of planned downtime days. Since this type of testing often requires shutting down the board (or stages of the board), it must be scheduled so that it does not affect production. When there is no inventory or planned downtime, electrical maintenance becomes what we call "fighting the fire."

What is electrical maintenance?

As the name suggests, electrical maintenance includes all the electrical components of the infrastructure. It is indispensable for industrial, public and residential buildings. Some examples of industrial and building maintenance tasks:

- Electric and electromechanical machines;

- Air conditioner or electric water tank;

- electric shower;

- Check sockets and electrical connections;

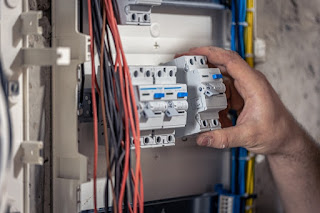

- Check electrical panels and circuit breakers;

- Measuring system voltage and current;

- General purpose lighting systems and appliances;

- Monitor components for wear and corrosion;

- Electrical damage repair.

Electrical Maintenance Technology

Most electrical maintenance is based on monitoring equipment condition, performing condition-based maintenance, and occasionally predictive maintenance. These are some techniques you can use:

- Preventive maintenance - including relays, circuit breakers, alternating current (AC), high voltage direct current (DC), and battery charging tests.

- Predictive Maintenance - Infrared testing that analyzes emissivity and reflectivity and temperature analysis.

- Troubleshooting Maintenance - Maintenance that attempts to troubleshoot safety and backup systems such as generators.

- Reactive (or corrective) maintenance - for unexpected failures, especially on less critical assets.

How to make an electrical maintenance plan step by step

follow these 8 steps to prepare an electrical maintenance plan:

- Asset criticality analysis

- Assess which failures are preventable

- Make a situation report with the team

- Prepare BOMs

- Insert all documentation in the CMMS

- Train staff

- Continuous improvement

- Realise your team’s capabilities