Siemens S7-1200 is a versatile programmable logic controller (PLC) that offers exceptional performance and flexibility for industrial automation applications. With its compact size and powerful features, the S7-1200 is widely used in various industries to control and monitor processes, optimize productivity, and enhance operational efficiency. In this guide, we will explore the key features, programming languages, communication options, and application examples of the Siemens S7-1200 PLC.

Key Features:

The Siemens S7-1200 PLC comes packed with several notable features that make it an ideal choice for small to medium-sized automation projects. Some key features of the S7-1200 include:

- Compact design: The compact size of the S7-1200 makes it easy to integrate into existing control panels or machine setups, saving space and installation efforts.

- Scalability: The S7-1200 offers different models with varying digital and analog I/O capabilities, allowing users to select the most suitable PLC based on their application requirements.

- High-speed processing: The S7-1200 is equipped with a fast CPU, ensuring efficient program execution and quick response times.

- Built-in communication interfaces: The PLC supports various communication protocols such as Ethernet, PROFIBUS, and PROFINET, enabling seamless integration with other devices and systems.

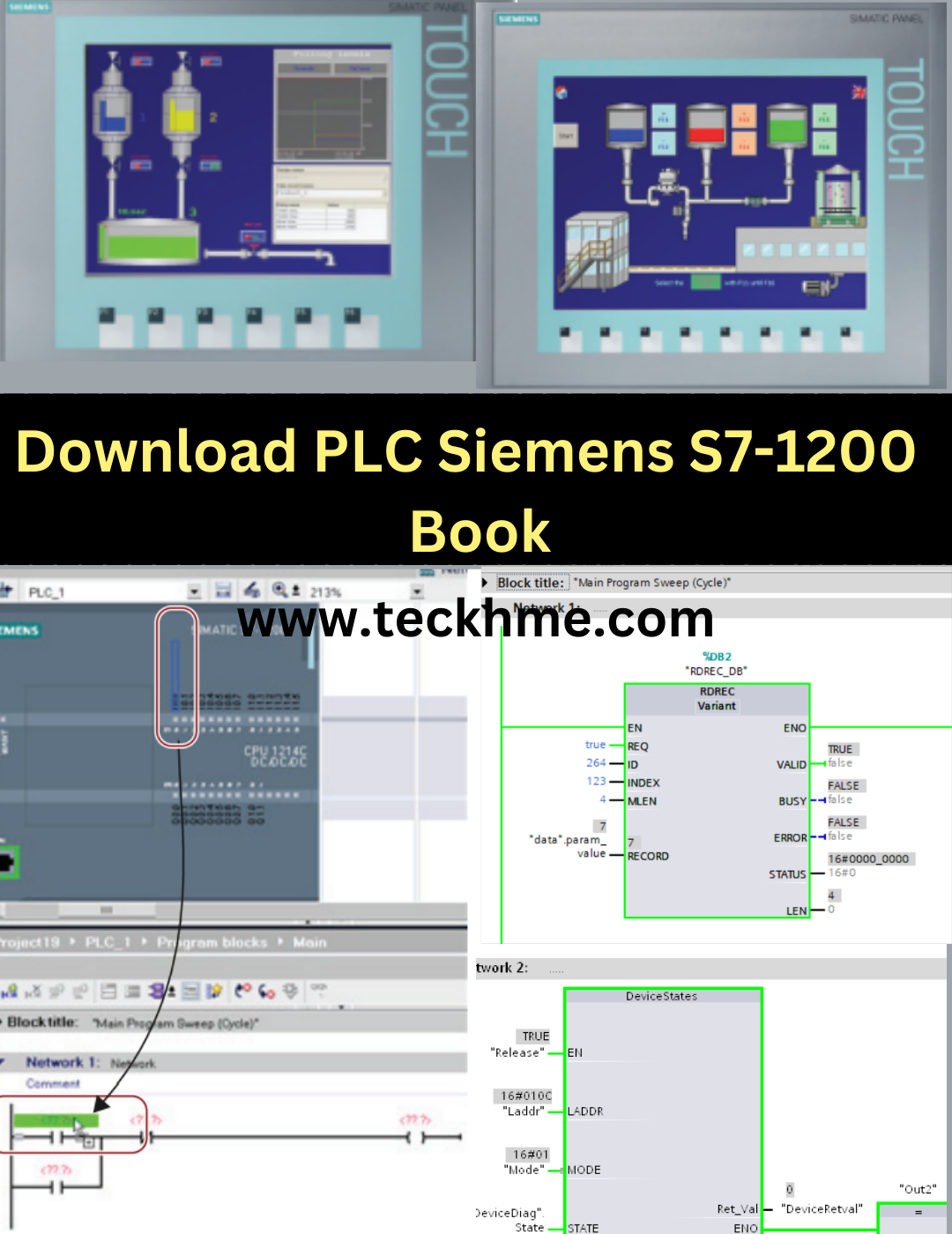

- User-friendly programming: The S7-1200 can be programmed using Siemens' intuitive engineering software, TIA Portal, which simplifies the development and maintenance of automation projects.

Programming Languages:

The S7-1200 PLC supports multiple programming languages, providing flexibility to programmers and allowing them to choose the most suitable language for their applications. The available programming languages for the S7-1200 include:

- Structured Control Language (SCL): SCL is a high-level language based on the standard programming language ST (Structured Text) and is particularly useful for complex programming tasks.

- Ladder Diagram (LAD): LAD is a graphical programming language that uses ladder logic symbols, making it easy for users with a background in electrical control systems to understand and develop programs.

- Function Block Diagram (FBD): FBD is a graphical language that utilizes function blocks to represent various control functions, offering a visual and modular approach to programming.

- Statement List (STL): STL is a low-level language that uses mnemonic instructions and is useful for programmers with a strong background in traditional PLC programming.

Communication Options:

The S7-1200 PLC provides various communication options, allowing seamless integration with other devices and systems. Some of the communication interfaces supported by the S7-1200 include:

- Ethernet: The built-in Ethernet port enables communication with other PLCs, HMIs (Human-Machine Interfaces), and SCADA (Supervisory Control and Data Acquisition) systems, facilitating real-time data exchange and remote monitoring.

- PROFIBUS: PROFIBUS is a widely used fieldbus protocol in industrial automation. The S7-1200 can be easily connected to PROFIBUS networks, allowing communication with other PROFIBUS-compatible devices.

- PROFINET: PROFINET is an advanced industrial Ethernet protocol that enables high-speed communication and seamless integration with other PROFINET devices, including drives, sensors, and remote I/Os.

- Application Examples: The Siemens S7-1200 PLC finds application in a wide range of industries and automation scenarios. Some common examples include:

- Manufacturing: The S7-1200 can control and monitor production lines, assembly processes, and material handling systems, optimizing efficiency and ensuring high-quality output.

- Building Automation: The PLC can be used to automate HVAC (heating, ventilation, and air conditioning) systems, lighting control,

- Food and Beverage: The S7-1200 can be employed in food processing plants to control mixing, packaging, and bottling processes, ensuring precise and consistent operations.

- Water/Wastewater Treatment: The PLC can manage and monitor water treatment plants, controlling pumps, valves, and filtration systems, and providing real-time data for process optimization.

- Renewable Energy: The S7-1200 can be utilized in solar and wind power plants to monitor and control power generation, grid synchronization, and energy storage systems.

- Automotive: The PLC can be integrated into automotive manufacturing processes, controlling robotic systems, conveyor belts, and quality control operations.

Purpose of Guide to the Siemens S7-1200 PLC

The purpose of the manual for the S7-1200 PLCs is to provide comprehensive information and guidance on installing and programming these PLCs. It is specifically designed for engineers, programmers, installers, and electricians who already possess a general understanding of programmable logic controllers.

The manual aims to assist users in effectively utilizing the S7-1200 series for controlling various automation applications. It covers essential topics such as installation procedures, hardware configuration, and the use of the Windows-based programming tool associated with the S7-1200 PLCs.

By providing detailed instructions and explanations, the manual enables users to leverage the compact design, cost-effectiveness, and powerful instruction set of the S7-1200 series. It serves as a resource that equips individuals with the necessary knowledge and skills to address a wide range of automation challenges using these PLCs.

DownloadNow

Conclusion:

The Siemens S7-1200 PLC offers a comprehensive and efficient solution for industrial automation needs. Its compact size, powerful features, and flexible programming options make it suitable for a wide range of applications. Whether it's controlling production lines, managing building automation systems, or optimizing energy consumption, the S7-1200 PLC provides reliability, scalability, and ease of use. By leveraging its key features, programming languages, and communication options, users can design and implement sophisticated automation solutions tailored to their specific requirements. The Siemens S7-1200 PLC stands as a reliable choice for achieving efficient and effective automation in diverse industrial sectors.

Learn Siemens S7-1500 PLC & HMI from Scratch using TIA PORTAL

Download Basic PLC Programming book

PLC Programming and SCADA Training book

Programming PLC for S7-1200/1500

SEE Electrical and PLC Programming: How to Program PLCs Using SEE Electrical

Download Basic PLC Programming book

Design and implementation of a conveyor belt system using PLC

Download Basic Principles of PLC Ladder Diagram Pdf

Arduino Home Automation Projects: A Beginner's Guide in PDF

PLC Programming Tools and Resources

Ladder Logic for the Arduino Opta PLC: Creating Your First Program