Introduction

Programmable Logic Controllers (PLCs) are the backbone of modern industrial automation systems, controlling everything from manufacturing processes to building management. Siemens' SIMATIC S7 series is one of the most popular and widely used PLC platforms in the world. If you're looking to enter the field of industrial automation or enhance your skills, a PLC-Basic Course with SIMATIC S7 is an excellent place to start.

In this article, we'll delve into the world of PLCs, explore the features and benefits of Siemens SIMATIC S7, and outline what you can expect from a PLC-Basic Course with SIMATIC S7.

Understanding PLCs

A Programmable Logic Controller (PLC) is a specialized computer used in industrial settings to automate and control machinery and processes. PLCs are designed to endure harsh industrial environments and can handle complex tasks with precision and reliability. They use ladder logic or other programming languages to execute tasks based on input signals and a programmed logic sequence.

PLCs are an integral part of industries such as manufacturing, automotive, food processing, pharmaceuticals, and more. They offer numerous advantages, including:

- Precision and Consistency: PLCs execute tasks with high accuracy and consistency, reducing errors and improving product quality.

- Flexibility: PLCs can be reprogrammed to accommodate changes in production processes or to add new functionality, making them adaptable to evolving industry needs.

- Remote Monitoring and Control: PLCs can be connected to networks, allowing for remote monitoring and control of industrial processes.

- Safety: PLCs can integrate safety features and emergency shutdown protocols, ensuring a safer working environment.

Siemens SIMATIC S7 Series

Siemens is a global leader in industrial automation, and its SIMATIC S7 series of PLCs is renowned for its quality, reliability, and versatility. The SIMATIC S7 family includes a range of PLC models suitable for various applications, from compact controllers for small machines to high-performance controllers for complex systems.

Key features of the Siemens SIMATIC S7 series include:

- Scalability: The SIMATIC S7 series offers a scalable solution, allowing you to choose a PLC that matches the complexity of your application.

- Integrated Safety: Safety is a top priority in industrial automation. SIMATIC S7 controllers come with integrated safety features that help you meet safety standards and protect your workforce.

- Efficient Programming: Siemens provides user-friendly programming software, such as TIA Portal (Totally Integrated Automation), which streamlines the development and maintenance of PLC programs.

- Diagnostics and Maintenance: SIMATIC S7 PLCs offer advanced diagnostic capabilities, making it easier to identify and resolve issues quickly, reducing downtime.

PLC-Basic Course with SIMATIC S7

A PLC-Basic Course with SIMATIC S7 is an introductory training program designed to equip individuals with the fundamental skills needed to work with Siemens PLCs effectively. Whether you're a beginner in the world of industrial automation or an experienced technician looking to update your knowledge, this course provides valuable insights and hands-on experience.

Here's what you can typically expect from such a course:

- Introduction to PLC Concepts: The course starts with an overview of PLCs, their history, and their importance in industrial automation.

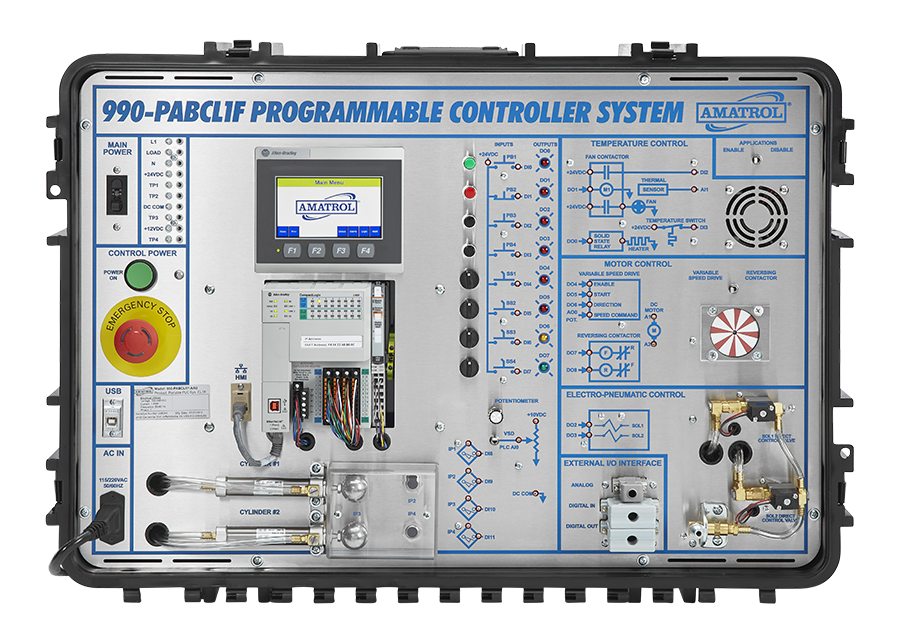

- Hardware Familiarization: Participants learn about the hardware components of Siemens SIMATIC S7 PLCs, including CPUs, I/O modules, and communication interfaces.

- Programming Basics: You'll dive into the basics of ladder logic programming using TIA Portal, including creating, editing, and downloading programs to the PLC.

- Hands-On Exercises: Practical exercises are a crucial part of the course, allowing participants to apply what they've learned in a real-world setting.

- Troubleshooting and Diagnostics: The course covers common issues that can arise in PLC systems and teaches participants how to diagnose and resolve them.

- Safety Considerations: Safety is paramount in industrial settings, and the course emphasizes the importance of safety features in PLC programming.

- Simulation and Testing: Participants gain experience in simulating and testing PLC programs before implementing them in actual machines or processes.

download

Conclusion

A PLC-Basic Course with SIMATIC S7 is a valuable starting point for anyone interested in a career in industrial automation or looking to enhance their skills in this field. Siemens' SIMATIC S7 series is a robust and versatile platform widely used in industrial settings worldwide. By gaining proficiency in working with these PLCs, you open up a world of opportunities in various industries and contribute to the advancement of automation technology. So, if you're ready to embark on this exciting journey, consider enrolling in a PLC-Basic Course with SIMATIC S7 today.