In today's industrial landscape, optimizing production efficiency and streamlining processes are critical for maintaining a competitive edge. Automated conveyor systems play a vital role in enhancing productivity by automating material handling and transportation. These systems, coupled with the power of structured text programming, offer a powerful solution for achieving seamless integration, real-time control, and efficient operation.

Automated Conveyor Systems: Enhancing Material Handling

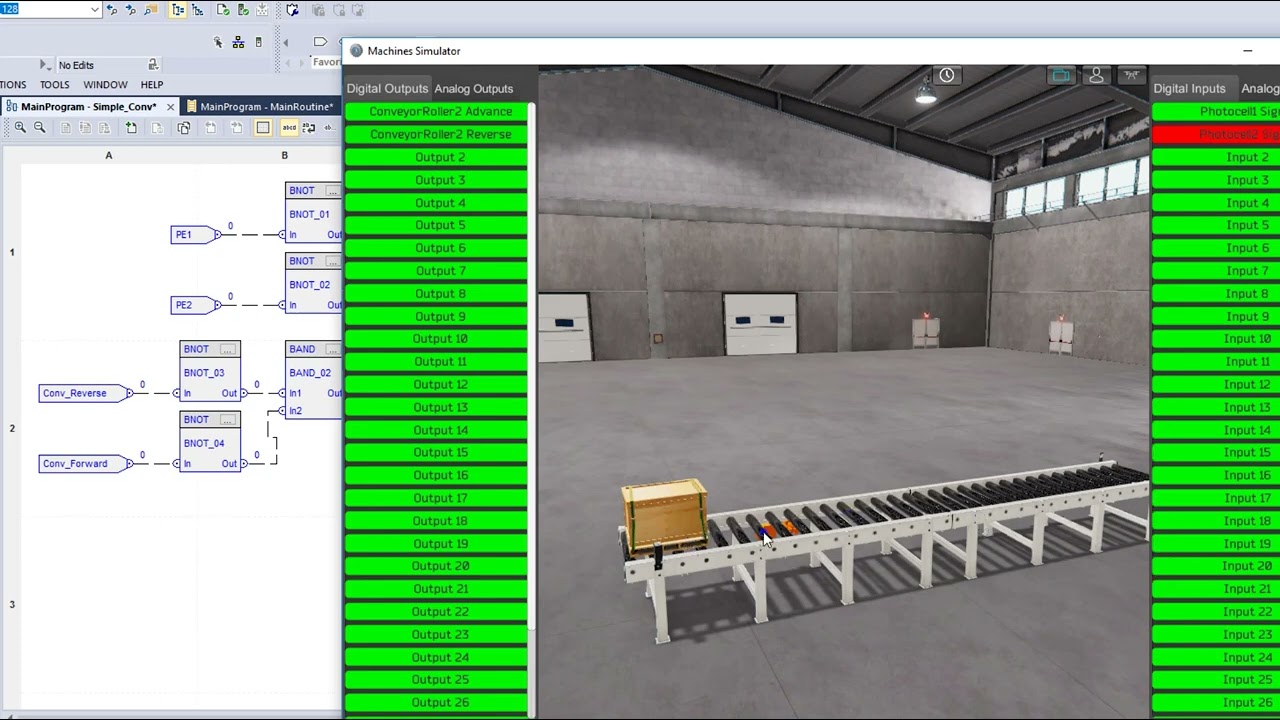

Automated conveyor systems consist of a network of motorized belts, rollers, and other components that facilitate the movement of goods or materials within a facility. By eliminating manual handling and reducing human intervention, these systems significantly improve efficiency, minimize errors, and enhance workplace safety.

Advantages of Automated Conveyor Systems:

- Increased Efficiency: Automated conveyor systems enable continuous and reliable material transportation, eliminating bottlenecks and reducing downtime. They ensure a smooth flow of goods from one production stage to another, optimizing overall operational efficiency.

- Improved Safety: By minimizing human intervention in material handling tasks, automated conveyor systems help reduce the risk of workplace accidents and injuries. They are equipped with safety mechanisms such as emergency stops, motion sensors, and automated error detection systems.

- Cost Reduction: Automated systems decrease the reliance on manual labor, leading to significant cost savings in the long run. These systems require minimal maintenance, resulting in reduced downtime and increased productivity.

- Flexibility and Scalability: Automated conveyor systems are highly versatile and adaptable to different production environments. They can be easily configured and modified to accommodate changing production needs, allowing for seamless integration with existing equipment.

Structured Text Programming: Unlocking the Power of Automation

Structured Text (ST) is a high-level programming language commonly used in industrial automation. It is based on the IEC 61131-3 standard, specifically designed for programmable logic controllers (PLCs). ST offers a structured and text-based approach to programming, making it ideal for developing complex control algorithms in automated conveyor systems.

Benefits of Structured Text Programming:

- Modularity and Reusability: Structured Text enables the development of modular and reusable code, simplifying program maintenance and enhancing code readability. It allows programmers to break down complex tasks into smaller, manageable functions, promoting efficient code reuse across different projects.

- Powerful Data Structures: ST supports data structures such as arrays, structures, and user-defined types, making it easier to organize and manipulate data within the program. This capability enhances the flexibility and scalability of the automation system, enabling it to handle large volumes of data efficiently.

- Real-Time Control: With its deterministic execution model, Structured Text is capable of real-time control in industrial automation applications. It offers precise timing control, synchronization, and event-driven programming, ensuring accurate and synchronized operation of conveyor systems.

- Seamless Integration: Structured Text can be seamlessly integrated with other programming languages, such as ladder logic or function block diagrams, allowing for a hybrid programming approach. This flexibility facilitates collaboration among programmers and enables efficient utilization of available resources.

5. PROGRAM AutomatedConveyorSystem

6. VAR

7. conveyorMotor : BOOL;

8. conveyorSensor : BOOL;

9. stopButton : BOOL;

10. startButton : BOOL;

11. alarm : BOOL;

12. speed : REAL;

13.

14. METHOD Initialize()

15. conveyorMotor := FALSE;

16. conveyorSensor := FALSE;

17. stopButton := FALSE;

18. startButton := FALSE;

19. alarm := FALSE;

20. speed := 0.0;

21. END_METHOD

22.

23. METHOD MainControl()

24. WHILE TRUE DO

25. IF stopButton THEN

26. conveyorMotor := FALSE;

27. ELSEIF startButton THEN

28. conveyorMotor := TRUE;

29. END_IF

30.

31. IF conveyorSensor AND conveyorMotor THEN

32. // Conveyor is running and an object is detected

33. speed := 1.0; // Set the conveyor speed to maximum

34. ELSE

35. speed := 0.0; // Stop the conveyor

36. END_IF

37.

38. IF conveyorMotor AND NOT conveyorSensor THEN

39. // Conveyor is running but no object is detected

40. alarm := TRUE; // Raise an alarm

41. ELSE

42. alarm := FALSE;

43. END_IF

44. END_WHILE

45. END_METHOD

46.

47. METHOD HMI()

48. WHILE TRUE DO

49. // Read inputs from the Human-Machine Interface (HMI)

50. stopButton := ReadStopButton();

51. startButton := ReadStartButton();

52.

53. // Update the HMI with system status

54. UpdateAlarmStatus(alarm);

55. UpdateConveyorSpeed(speed);

56.

57. DELAY 100; // Delay between HMI updates

58. END_WHILE

59. END_METHOD

60.

61. METHOD ReadStopButton() : BOOL

62. // Code to read the status of the stop button

63. // and return a BOOL value

64. END_METHOD

65.

66. METHOD ReadStartButton() : BOOL

67. // Code to read the status of the start button

68. // and return a BOOL value

69. END_METHOD

70.

71. METHOD UpdateAlarmStatus(alarmStatus : BOOL)

72. // Code to update the HMI with the alarm status

73. END_METHOD

74.

75. METHOD UpdateConveyorSpeed(conveyorSpeed : REAL)

76. // Code to update the HMI with the conveyor speed

77. END_METHOD

78.

79. // Main program

80. METHOD Main()

81. Initialize(); // Initialize variables

82.

83. // Start parallel tasks for control and HMI

84. PARALLEL(MainControl(), HMI());

END_METHOD

Conclusion

Automated conveyor systems, combined with the power of Structured Text programming, offer a robust solution for optimizing production efficiency in industrial environments. These systems enhance material handling, improve safety, reduce costs, and provide the flexibility to adapt to changing production requirements. Structured Text programming, with its modularity, powerful data structures, and real-time control capabilities, enables precise control and efficient management of conveyor systems. As industries continue to evolve, leveraging the potential of automated conveyor systems and Structured Text programming will be vital in achieving maximum productivity and competitiveness.

Learn Siemens S7-1500 PLC & HMI from Scratch using TIA PORTAL

Download Basic PLC Programming book

PLC Programming and SCADA Training book

Programming PLC for S7-1200/1500

SEE Electrical and PLC Programming: How to Program PLCs Using SEE Electrical

Download Basic PLC Programming book

Design and implementation of a conveyor belt system using PLC

Download Basic Principles of PLC Ladder Diagram Pdf

Arduino Home Automation Projects: A Beginner's Guide in PDF

PLC Programming Tools and Resources

Ladder Logic for the Arduino Opta PLC: Creating Your First Program